(This article is re-formatted from the following publication:

Mustacich, R. 2015. Fake Perforations on 19th Century U.S. Revenue Stamps: A

Stroke of Luck. The American Revenuer, 68(4): 90-96.)

Fake Perforations on 19th Century U.S. Revenue Stamps: A Stroke of Luck

By Robert Mustacich

Figure 1. Typical examples of genuine (original perforation error) and fake extra perforations on U.S. revenue stamps. In the left multiple, the perforation was apparently halted leaving partial rows of perforations in the sheet, perhaps because the sheet was at an angle in the perforator. An accidental second pass through the perforator was a common genuine error as shown in the top center example. While occasionally the fake extra perforations mimic genuine perforations, they are usually more fanciful as shown by the remaining three examples: extra perforations at odd angles, often crossing the interior of the stamp, and extra perforations near the edges that have spacings that could not result from a second pass through the perforator.

My initial research on fake extra perforations on 19th century U.S. revenue stamps confirmed the idea that all of these forgeries were done by a single individual, likely in the early 1890s. [1] I became interested in exploring more aspects of this story: What equipment might he have obtained? How might he have learned about this opportunity? Could circa 1890 equipment explain some of the peculiar features of the forgeries? I was especially interested in testing old perforation equipment to learn how a vintage perforator operated and could have created these forgeries. As luck would have it, I was able to buy on eBay a small table-top perforator from this time period. I had not seen any of this model in previous years, and none since this acquisition, so this was truly a stroke of luck for me.

In a previous research project, I investigated a large collection of 19 th century U.S. revenue stamps, all having extra perforations, to develop a method of distinguishing between genuine, original perforation errors and fake extra perforations. Using computer analysis of high resolution images of the extra perforations, I found that irregularities in the hole spacing provided patterns that could be used as a “fingerprint” to match up rows of perforation all done by the same individual perforator. Amazingly, all of the extra perforations known to be fake have an identical fingerprint, thus were done on the same specific device. This research was published in The American Revenuer in early 2014 in the article “Freak or Fake” (Mustacich, 2014). Examples of these stamps with genuine and fake perforations are shown in Figure 1.

Sterling Ups the Ante

We can assume with certainty that the perforation forger knew enough about revenue stamps to recognize the opportunity when it arose. It is not apparent that any special commercial value had been given to perforation oddities in the earliest days of stamp collecting. This situation changed dramatically when the great U.S. revenue specialist E. B. Sterling documented them and attached premium prices to them in his great catalogues (Nast, 1908). His fifth edition of “Sterling’s Standard Descriptive and Price Catalogue of the Revenue Stamps of the United States” in 1888 long stood as one of the primary references for collectors of U.S. revenue stamps, thanks to his extensive collection (later sold to H. E. Deats) and his detailed documentation and pricing of stamp varieties. I found that his descriptions of extra perforations are nearly all consistent with what have been found to be genuine extra perforations created in the original perforation process (Mustacich 2014), and these original perforation errors were known to occur in small numbers for most of the U.S. revenue stamps. His catalog pricing of these oddities in dollars rather than pennies, at least for the more common stamps, provided a strong temptation; the timing seems to be about right for an emboldened forger to get to work around 1890. Recollections of sudden appearance of large quantities of stamps with extra perforations by auctioneers and the sighting of stock books filled with these stamps has been traced to the early 1890s, and by 1902 there was such a supply that even large stamp companies were offering steeply discounted perforation “freaks” (Nast, 1908).

Forging Ahead

Anyone with philatelic knowledge would know that duplicating the perforation process used for federal postage and revenue stamps would be nearly impossible, as true today as in 1890. It is doubtful that enough profit could be made from fake perforations to cover the cost of a complicated rotary perforating machine used for this task. So the forger had to be aware of other, smaller perforating devices, and discerning enough to choose a type which most closely mimicked the gauge of the rotary machine, 11.8-12.2. The resulting choice was a stroke perforator, which probably could be found in print shops, as perforating was becoming popular for banking uses. How difficult or expensive would it have been to acquire this machine? As luck would have it, just at the time that the value of perforation oddities soared, the late 1880s, the table-top stroke perforators were likely becoming obsolete (and hence available) with the introduction of much easier-to-use, floor-standing perforators.

The purpose of this research was to explore the route that this forgery could likely have followed. The questions I grappled were the following: (1) What perforators were readily available to a forger circa 1890? (2) How might the option of using a stroke perforator have occurred to the forger? (3) Were there small production, philatelic items that were stroke perforated with the proper gauge c. 1890? (4) What could I learn hands-on about the perforation process that could shed any light on these forgeries?

Commercially Available Stroke Perforators Circa 1890

I searched the U.S. patent literature and the internet (old advertising, antique office machinery) and found that there were at least two prominent businesses that manufactured small stroke perforators in their early days of operation, specifically the 1880s. They were the F. P. Rosback Co. and the B. F. Cummins Co., both of Chicago. Table-top, hand-operated stroke perforators appear to have been very early products of both companies. Both companies quickly moved on to other products that they became better known for. The Rosback Co. developed a line of floor-standing, easier-to-operate perforators and remained in the perforation business, while the Cummins Co. appears to have abandoned stroke perforators for a line of products used for check cancellation.

The published history of the F. P. Rosback Company cites meager information regarding its earliest perforation products, only that the founder started the company in 1881 to pursue the manufacture of specialized machinery, finding himself surrounded by printers in the new business of perforating paper for the banking industry so that the paper could be easily torn (The Rosback Co. 1981). It is known that the founder, while pursuing his varied inventions in the early days of his company, such as metal planers and sheet metal fence posts, did a number of repairs to perforating equipment owned by local Chicago printers.

The earliest Rosback Co. perforator patent that I could find, U.S. No. 374880, was filed in 1886 and describes an improvement to a hand-operated perforator of extremely similar design to the one I obtained. The patent reveals improvements to the row of pins in which the pins are backed by multiple slugs which can be selectively removed so that only desired patterns of pins backed by remaining slugs will perforate the paper.

The earliest perforators discussed in the Rosback Company history focus on their popular foot-operated and later mechanized table-top perforators for which U.S. patent 387543 was filed in 1887. It appears that the company developed this floor-standing, more capable, and easier-to-operate perforator soon after the table-top, hand-operated product. These greatly-improved, floor-standing perforators likely obsoleted the hand-operated models quickly in print shops, especially because the small models were so difficult to use. Cinderella stamps are still perforated by the larger, foot-operated stroke perforator today (The Olathe Poste, 2015). However, the Rosback Company may be best known to modern philatelists for their determined effort to manufacture a rotary perforator in the early 20 th century that was used to perforate the 1919 U.S. 1c postage stamp with 12.5 gauge (The Rosback Co. 2015; Weiss, 1994).

A hand-operated perforator is also known to have been produced by the B. F. Cummins Company, also of Chicago. This company and its perforation products date back to 1887 according to company advertising (Early Office Museum, 2015). Similar to the Rosback Company, the Cummins Company is not remembered for their table-top, hand-operated perforator. Rather, the early Cummins Company is best known for their date punching cancelers that were very popular with financial institutions for canceling transactional documents. Contact with the modern company showed that there was familiarity with these date cancelers from the earliest days of the company, but not with the hand-operated, linear perforator similar to the Rosback perforator discussed above. Like the Rosback Company history, this type of now-forgotten product appears to have been eclipsed by the success of their later products, and it was likely to have also been obsoleted by the more advanced Rosback perforators of the late 1880s.

Reducing to Practice

After learning about the historical context in which these forgeries were done, I wanted to understand more about the actual process. Acquiring an antique Rosback table-top stroke perforator on eBay enabled me to investigate further the methods possibly used by the forger. I was very curious to see how the general characteristics and fingerprint of this perforator compared with the forged perforations.

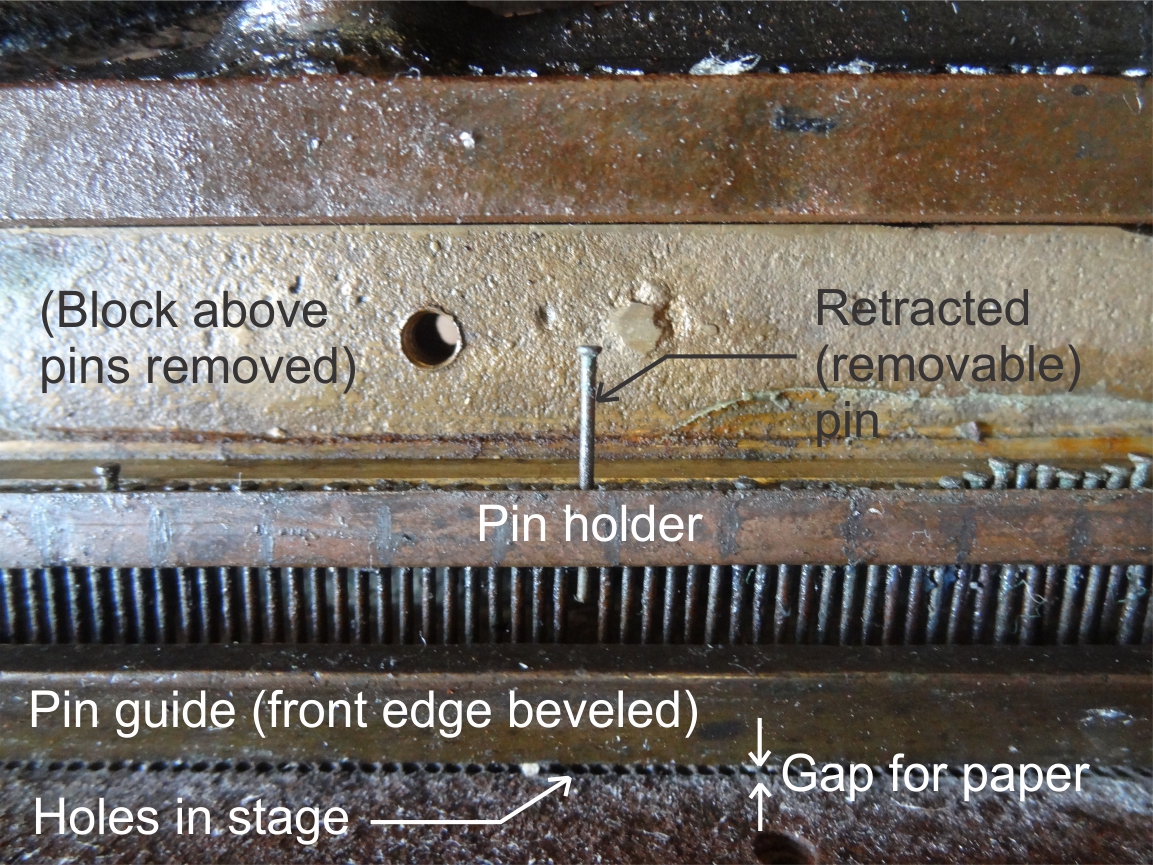

A photo of the early Rosback perforator I obtained on eBay is shown in Figure 2. This hand-operated machine uses a lever to drive a row of perforating pins through a guide above a metal stage with precisely aligned holes. The paper fits in the narrow gap between the guide and the stage, similar to a 3-hole paper punch. The perforator I obtained may be a very early model, having only a metal block above the entire row of pins in the blade, or perhaps this block was an option to replace an assembly of slugs. Figure 3 shows a picture with this block removed. One of the pins is mostly retracted showing the design of the replaceable pins. This perforator has a capacity of about 150 pins, resulting in a pin row with a length of approximately 10 inches. The date of the earliest Rosback Co. patent suggests that the model I obtained may date to 1886 or earlier, and that the first patent may describe proprietary improvements to this more basic, and perhaps non-proprietary, design.

Figure 2. A Rosback Co. table-top perforator believed to be one of their earliest, pre-1890 products. It weighs 40 lbs and requires a force of 50-80 lbs to punch the 10 inch row of pins through one or a few layers of paper. It is gauge 12 and has an average hole size matching the fake extra perforations. By using more than one layer of paper, the sharpness of cut also matches the fake extra perforations. A 0.75L bottle of champagne is shown for size reference.

Figure 3. A close-up view of the row of pins in the Rosback perforator with the block above the pins removed. One pin is partially removed to show the design of the pin. The pins are lowered through the pin guide when the handle is pressed, and the paper on the stage is punched when the pins enter into the holes in the stage. The pin guide is beveled on the front side so that the location of pin entry to the paper can be viewed. The punched holes are slightly smaller than the pin diameter, an effect apparently resulting from the much larger hole sizes in the stage.

An interesting feature of this perforator is that the user is able to see the action of the pins from the front side only, as this view is blocked from the back by the pin guide. Thus, placement of a stamp for perforation needs to be done from the front. This one-sided access would be consistent with the perforation rotations generally observed with multiple fake perforations on the same stamp, each near a different edge of the stamp; multiple extra perforations along the edges of the stamp could be simply done by twirling the stamp and punching each edge, in effect rotating the perforation patterns about the edges (Mustacich 2014).

Another feature of this table-top Rosback perforator is the large amount of force required to operate it. A force of 50-80 lbs is required to punch the row of pins through the paper, depending whether a single sheet or a few sheets are being perforated. This is evidently why the perforator has such a sturdy design with a large handle and weighs 40 lbs. The descent of the pins to the paper is irregular over the length of the row of pins, and this may be a deliberate design to spatially spread the punching over the length of the row to ease somewhat the resistance by not having all of the pins punch simultaneously. Consequently, an insufficient effort easily produces so-called “blind perfs” resulting from an incomplete descent and penetration by all of the pins. Repetitions of these are occasionally observed in fake extra perforations on U.S. revenue stamps, and these provided an early clue of stroke perforation (Brett 1990). These are clearly a result of this type of perforator used with insufficient force.

Yet another feature of the forgeries was the production of some with partial rows of perforation, an obvious effort to imitate genuine perforation errors with partial rows. This suggests that a stroke perforator used for making forgeries had sufficient working room around at least one end of the perforator. The design of the hand-operated Rosback and Cummins perforators has a freely open end of the pin row opposite the support for the handle. This open end would provide sufficient space for stamp positioning and view to fabricate partial row fakes.

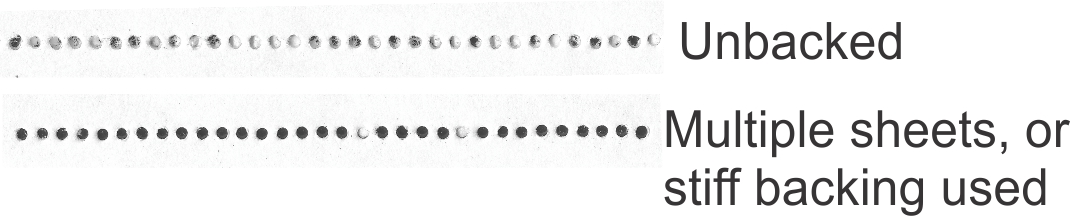

I discovered that this early Rosback perforator performs better on multiple sheets or heavy paper than on thin paper. Several sheets of paper, or one sheet backed with cardstock results in sharper hole cuts, while single sheets of thin paper result in poorer punches or punches leaving some of the chaff still partially attached as shown in Figure 4. The perforation results using several sheets are very similar to historical fake extra perforations on revenue stamps. This approach provides relatively smooth, sharp perforation with an average hole radius of 0.481 ± 0.017 mm, an average gauge of 11.82, and an average hole fit error (HFE) [2] of 10.2 ± 1.2. These results compare very favorably with the average hole radius for the fake perforations in the 19th century U.S. revenue stamps of 0.483 ± 0.007 mm, an average gauge of 11.91, and an average HFE of 9.4 ± 0.9. This approach, at least with this specific perforator, would closely match the hole properties of the forgeries.

Figure 4. A comparison of punched holes for a single sheet of paper with layers of paper or paper backed with a stiff layer. Because of the large hole sizes in the stage, a stiffer backing sheet or 2-3 layers of paper gives a sharper hole cut to the top layer.

I investigated the difficulty of punching clean holes in thin paper, and realized that it results from the relatively large “pin clearance,” or greater size of the drilled hole in the stage than the pin that punches down into it. Given the difficult machining challenges of fabricating a perforator with small tolerances and precise alignment of pins with drilled holes, it is not surprising that the clearances for this early machine are at the very loose end of the range. I measured perforation pin diameters of approximately 0.0395 inches, a size equal to the replacement pins provided recently to me by The Rosback Company. Nearly all of the stage holes that receive the pins for punching the holes are larger than 0.043 inches, but less than 0.047 inches. Using the middle of this range gives an estimate of approximately 0.005 inch for the clearance of the pins in the holes. My correspondence with the U.S. Bureau of Engraving and Printing (BEP) indicates that the pin clearances of their rotary perforators ranged 0.001-0.0045 inch depending on the perforator, with the larger clearances associated with their older perforating equipment (U.S. Bureau of Printing and Engraving 2013).[3] So the pin clearance on an antique machine is apt to be quite large.

In the process of taking measurements, I noticed a curious fact: the diameter of the punched hole is actually a bit smaller than the pin. This turned out to be another result of the large pin clearance. There is a small discrepancy of about 4% between the average, punched hole size of 0.96 mm diameter and the pin size, approximately 1.00 mm diameter. Based on my research, this appears to be the result of the flexibility of the paper when the clearance of the pins in the holes is large. With a very small clearance the pin should better shear the paper to create a hole close to the size of the pin diameter, but a large clearance can allow the paper to stretch under the pressure of the pin before it yields to the punch. The relaxation of the stretched paper after punching can result in a small reduction of the achieved hole size. I investigated this by making my own single-pin punch and varying the clearance of the pin the stage hole. [4] The punched hole sizes were very close to the pin diameter for the small clearances. These holes were about 1% smaller than the measured pin size. For the larger clearance values, the average hole sizes were 2-4% smaller than the pin size depending on the layering of the paper. It appears that this effect links the smaller hole sizes to the estimated hole clearances for the pins. These results are also consistent with communication from the BEP which stated that in some cases the stamp perforation holes can be smaller than the pin diameters used to punch the perforations, although no explanation was offered by the BEP for such discrepancies (U.S. Bureau of Engraving & Printing 2013).

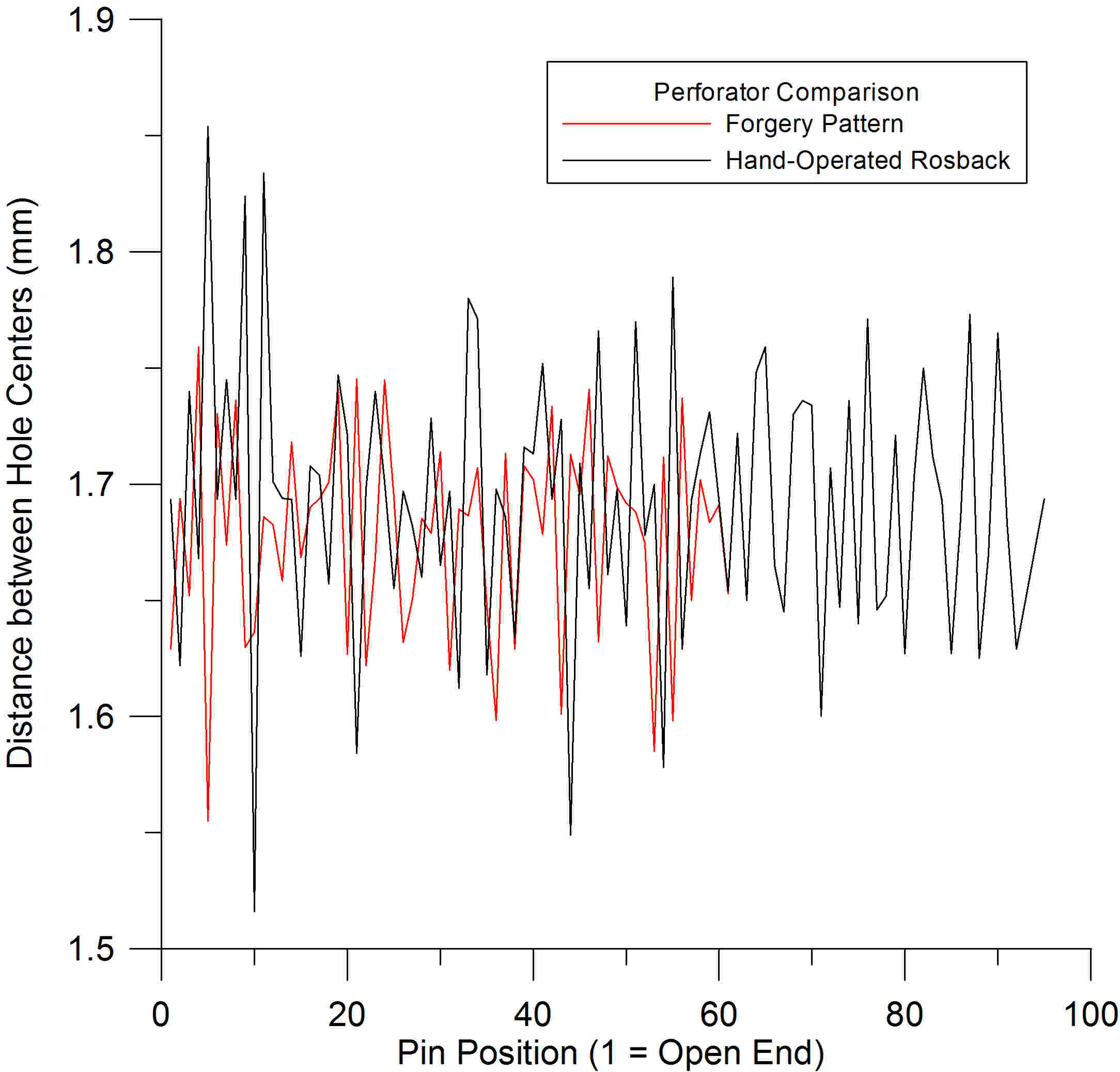

How similar are the perforations of my Rosback machine to the original forgeries? The gauge is indistinguishable, as are the hole radii and sharpness of cut when used optimally. So this particular perforator is an excellent match. However, each individual machine has its own inconsistencies, due to the microscopic imprecision in machining the row of pins, what I have referred to as the “fingerprint.” Comparing my machine with perforation forgeries on stamps, the unique fingerprint of each machine is evident. An overlay of the sequence of hole spacing for my perforator and a calculated sequence of hole spacing derived from an analysis of the forgeries is shown in Figure 5. Both show varying and imperfect pin spacing, but without significant correlation in their patterns. This is not surprising since the actual perforator used for the forgeries with its unique fingerprint may have become landfill more than a century ago.

Figure 5. A comparison of the fingerprint of this specific Rosback perforator with the fingerprint pattern of the fake extra perforations on U.S. revenue stamps. The fingerprint consists of the sequence of spacings between the consecutive holes in the punched pattern. The small irregularities in this spacing arise from the imprecision in manufacturing (i.e., the inability to achieve a perfect spacing). The chance of a fingerprint match was considered remote, but the general perforation characteristics of this Rosback perforator are an extremely close match to the forged perforations on the U.S. revenue stamps.

Legitimate Uses?

Aside from fake perforations, was a stroke perforator employed for any other philatelic uses c. 1890? Were there examples of stroke perforation on back-of-the-book stamps that could have drawn the attention of a stamp dealer looking for alternatives to rotary perforation for the purpose of forgery? With these questions in mind, I studied a number of stamps produced by sources other than the printers of the federal revenue stamps. I cast the net very broadly out of curiosity to look for any stamps with similar perforations. Images of perforations were analyzed for their general characteristics such as gauge, hole sizes, and sharpness of hole cuts, as well checking the perforation fingerprints for evidence of stroke perforation.[5] To my knowledge, analysis of this type has not been done before.

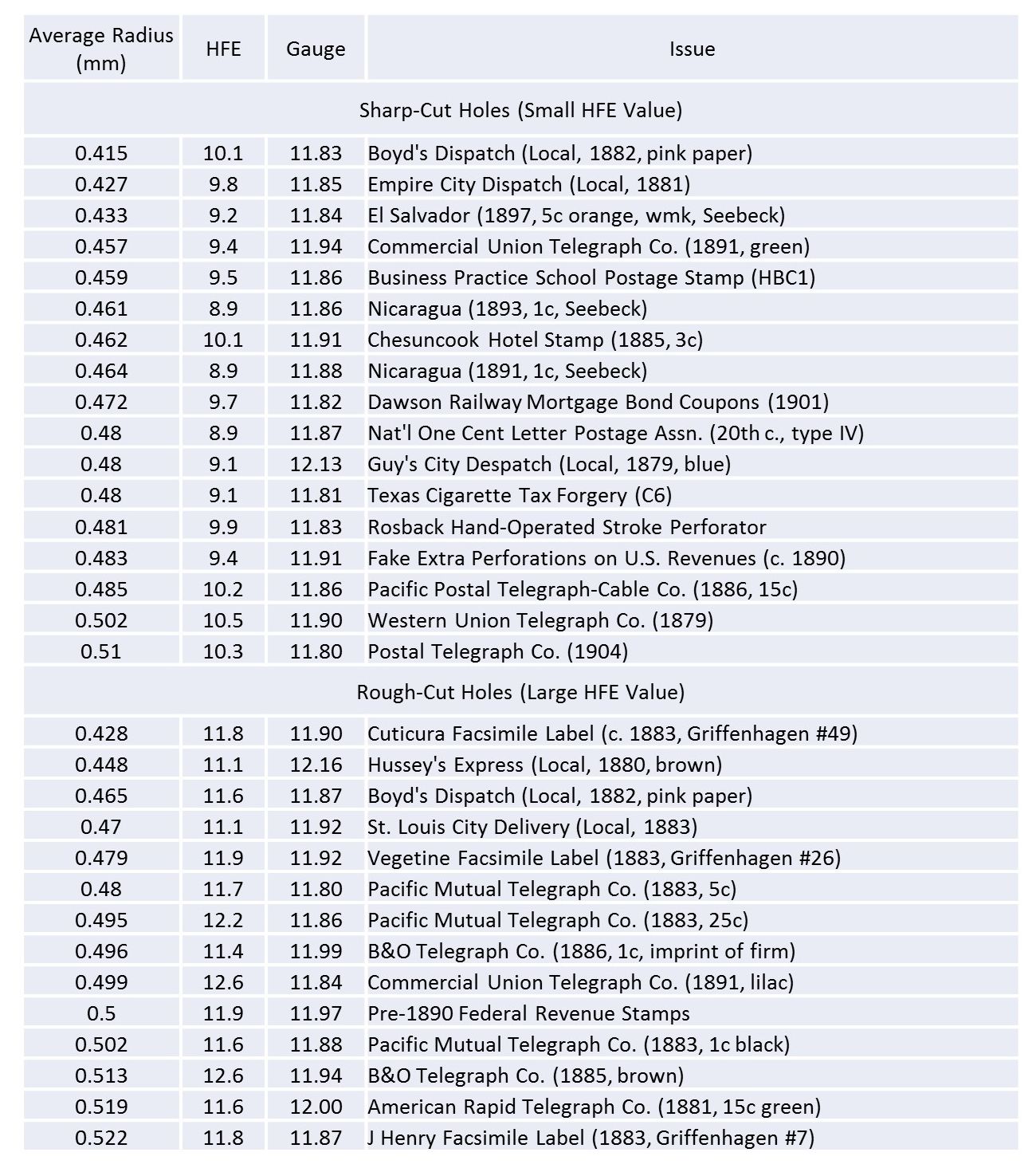

The results of this small survey are listed in Table 1. Only perforations with a gauge in the range of 11.8-12.2, a range that encompasses the genuine and forged extra perforations on revenues, are included in this table. The table is divided into two groups based on a measure of the sharpness and circularity, the HFE (see footnote 2). Most of the forgeries have an HFE value less than 11, indicating relatively smooth, round sharply-cut holes. The upper group in Table 1 has HFE values less than 11, and are sorted in order of increasing hole radius. The lower part of the table has larger HFE values that are associated with typical rotary perforation, a process generally resulting in rougher cut holes. The average value of HFE for pre-1890 federal revenue stamps is 11.9 and is shown as a bolded entry in the lower group in Table 1. Forgeries have a range of radius values of 0.47-0.49mm, and radii in this range are bolded in the table to focus attention to stamps having similar hole sizes to the forgeries.

Table 1. A survey of perforation characteristics for a wide range of back-of-the-book stamps having a gauge in the range of 11.8-12.2. The HFE is a measure of the circularity and sharpness of the hole cut (see footnote 2). The upper section of the table contains stamps all having relatively sharp hole cuts (HFE < 11). Entries in red are stamps considered to be stroke perforated. The lower section of the table consists of stamps with higher average HFE values because of their rough cut holes. The bolded fifth-to-last entry shows the average value for rotary-perforated U.S. revenue stamps. Both sections of the table are sorted in order of increasing hole size, and the range of hole sizes (0.48mm +/- 0.01mm) found for the forged extra perforations are bolded to highlight the stamps having hole sizes similar to the stroke-perforated forgeries. A cluster of stroke-perforated stamps occurs in this range in the upper portion of the table.

Items showing strong evidence suggesting stroke perforation are colored red in the table. Interestingly, the stroke-perforated items are clustered together on the table. The characteristics of the fake extra perforations on 19th century U.S. revenues is shown as a bold red entry in Table 1. The characteristics of the Rosback stroke perforator is also shown in bold red in the table. All of the items in the survey were tested where possible for evidence of stroke perforation. This typically requires a stamp multiple so that multiple perforation rows are available for analysis and accurate fingerprint matching. Alternatively, repeating blind perfs or related features in non-parallel rows of perforation can sometimes be observed to provide evidence of stroke perforation.

The items in the table include a range of U.S. locals, telegraph company stamps, some proprietary medicine facsimile stamps, some stamps produced by N. F. Seebeck for Latin American countries, and some cinderellas. One example of a document, the one-of-a-kind Dawson Railway $3,000,000 mortgage bond of 1901, has several pages of handwritten coupons which were custom perforated, and the matching fingerprints clearly show the coupon pages were stroke perforated. Repeating fingerprint patterns were also found in a large block of the National One Cent Letter Postage Association stamps from the 20th century. The row alignments are also irregular suggesting manual perforation. The Pacific Postal Telegraph-Cable Co. appears to be stroke perforated based on the matching of fingerprints in a pane of stamps. No determination regarding stroke perforation could be made regarding the Guy’s City Despatch or the Texas Cigarette Tax C6 forgery without a sufficiently large multiple of the stamps to accurately compare fingerprints, although the Guy’s City Despatch stamp may pre-date the simple stroke perforators mentioned in the article.

Another conceivable source of a row of punched holes for perforation forgery is a perfin punch, but the use of perfins dates to later years than the forgeries. There are many perfins which include both a top and bottom horizontal row of evenly spaced and uniform holes. Out of curiosity, an examination of compiled perfin images (Mongan 2010) did not produce any examples of perforation sufficiently similar to the perforation range in Table 1. The closest gauge values to the forgeries (11.8-12.2) found in these perfin patterns were 11.0 and 12.8.

It appears from this brief survey of stamps produced by other sources than the federal revenue stamps that several could have been produced by stroke perforation. These stamps include the Pacific Postal Telegraph and Cable Co., the Texas Cigarette Tax forgery, and the type IV National One Cent Postage Association stamp. Additional stamps near this group in Table 1, such as the Chesuncook Hotel stamp, might join this group if larger blocks can be analyzed. So at least in the case of the stamps of the Pacific Postal Telegraph and Cable Co., there is a contemporaneous example of stamps produced in small quantities that were perforated by similar stroke perforation to that used by the forger. Because the forger must have been a specialist in stamps, stamps such as these telegraph stamps that were specially perforated in small panes could have caught his attention. Contact with the printer of these stamps would then have provided the information for the perforation equipment needed for the forgery. Alternatively, the increasing use of perforated products in the banking industry, or a visit to a print shop that happened to have a perforator, could have also provided guidance on sourcing a perforator that was well suited to the intended forgery. [6]

Summary

This study shows that the characteristics of the 19th century revenue perforation forgeries are well matched by an exemplar hand-operated perforator of a design thought to be sold by the F. P. Rosback Co. before 1890. Also, there are a number of other back-of-the-book stamps that appear to share similar perforation characteristics, some of which appear to be stroke perforated in small batches such as panes. Perhaps fortunately for the forger, the hand-operated perforators may have become obsolete by the early 1890s and readily available from print shops switching to the much easier to use, foot-operated perforators. So the forger probably made a profit from selling his fake perforations, but it was likely at the expense of his reputation, as we can see from this later account: “… most of them, if not all, came from one source, a stamp dealer then quite active in New York, who had acquired a perforating machine, and who was already a suspect in connection with many other forms of fakery, such as the altering of stamps and the affixing of stamps to covers, quite a nefarious character” (Turner, 1961).

References

Brett, G. W. 1990. Some Aberrant 19th Century U.S. Revenue Stamp Perforations. The American Revenuer 44 (September):163-172.

Early Office Museum 2015. http://www.officemuseum.com/check_protector_gallery_cancelers.htm

Griffenhagen, G. B. 1969. Private Die Proprietary Medicine Stamps. Vol. 4 Medical Series, Handbook No. 66, American Topical Association, Milwaukee, WI, pp. 70-77.

Mongan, A. J. 2010. A Handbook of Perforated or Punched Initials, Numbers and/or Designs in United States Revenues and Fiscal Documents, Volume I, Transaction Revenues, The Perfins Club, APS Affiliate 57.

Mustacich, R. 2014. Freak or Fake? A New Fingerprinting Method for Distinguishing between Original and Fraudulent Extra Perforation of 19th Century Revenue Stamps. The American Revenuer 67(First Quarter): 2-19.

Nast, C. A. 1908. Freak Perforations. Carter’s Messenger 1: 74-75.

The Olathe Poste 2015. The Olathe Poste, Olathe, CO. http://www.theolatheposte.com

The Rosback Co. 1981. The History of Rosback 1881-1981. The Rosback Company, St. Joseph, MI.

Toppan, G. L., Deats, H. E., and Holland, A. 1899. An Historical Reference List of the Revenue Stamps of the United States, Newcomb & Gauss, Salem, MA, reprinted by Castenholz and Sons, Pacific Pallisades, CA, 1990.

Turner, G., compiler. 1961. Sloane’s Column. West Somerville, MA: Bureau Issues Association, Inc. p. 394.

U.S. Bureau of Printing & Engraving, U.S. Dept. of the Treasury, 2013. Reprinted private communication dated July 4, 1964, original recipient redacted.

Weiss, L. S. 1994. Specialist Gauge Measurements, in Perforation Measurements of United States Stamps, Bureau Issues Association, Inc., Reprint Series No. 2, The United States Specialist, Katy, TX.

[1] There is opinion cited in the early literature that these forgeries were produced by a New York stamp dealer around 1890. This dealer had acquired a perforating machine, and was already a suspect in connection with many other forms of fakery (Turner, 1961).

[2] The hole fit error (HFE) is a measure of the overall error in fitting a circle to the outline of a hole as calculated from a high resolution image (Mustacich 2014). More circular and sharply cut hole edges result in better circle fits and smaller values of the HFE.

[3] Please note that the early revenue stamps pre-date direct BEP experience with perforators, and the early non-BEP perforation equipment may have been of lesser quality.

[4] I drilled a pin guide in a 3/8 inch block of aluminum and aligned a lower plate below this block with a gap for punching paper. The lower plate was drilled with a variety of hole sizes providing pin clearances ranging from 0.003 to 0.007 inches. New replacement pins of 0.0395 inch diameter from the Rosback Company were used for punching.

[5] The analysis of perforations between multiples of stamps were used wherever possible since a complete image of each hole gives the most accurate measurements of the hole sizes (Mustacich 2014).

[6] I have found examples of fancy 1889-1890 bank checks with perforated stubs having a gauge of 11.8-11.9, and these were probably low production items that were stroke perforated, but I do not have enough examples or information to demonstrate this point.